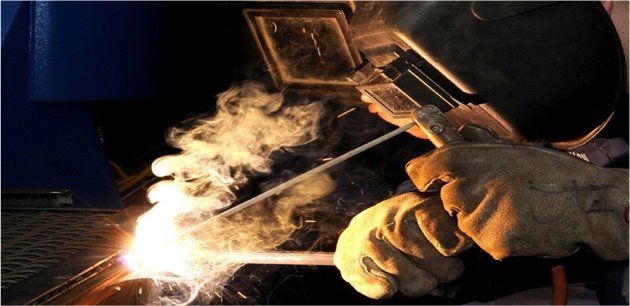

The Pros and Cons of Stick Welding

Its official name is Shielded Metal Arc Welding (SMAW), but it’s usually called stick welding. This type of welding employs an electrode (stick) and can be used for welding almost all the ferrous metals and other metal types, too. It is among the most widely-used welding processes.

During stick welding, the electrode or welding rod, which has a flux-coated core wire, is used to carry the current and provides most of the metal weld. After the electrode tip touches the metal surface, high heat energy melts both the rod and metal base and creates the weld.

As the flux coating vaporizes, it forms a layer of gas and slag that protects the weld from any contamination. The welder then chips the slag off the weld bead after welding is completed.

Because of its portability, stick welding is used in fields like heavy equipment repair, construction, pipeline welding, and similar industries.

Like other methods of welding, stick welding has its defenders and detractors. Here are some of the pros and cons of this oldest method of welding.

Stick Welding Advantages

Stick welding has certain distinct advantages:

- Stick welding is effective even when it’s windy or raining

- The equipment required is not very expensive

- It needs no external shielding gas, which saves money

- It’s less sensitive to paint, corrosion, and dirt at the welding point, saving time on pre-welding clean-up

- It’s easy to change rods for different metals

- The ground clamp can be attached far from the welding point

Stick Welding Limitations

To be fair, there are some disadvantages:

- Compared

to other methods of welding, stick welding is slow

- It

is a more complicated process, which

requires a welder with skill and experience in stick welding

- It

is time-consuming to chip away the slag that formed during the weld

- It

can be difficult to weld thinner metals

- The

welding rods must be replaced more

frequently than in other types of welding

- There

can be excessive spatter, rough surfaces, and porosity with stick welding

Make Sure You Hire Skilled Welders

At Van Industries we employ highly skilled welders, so you can be confident that your work will be in experienced hands. Although in most cases other welding options are preferred, if stick welding is best for your project then our professional welders can deliver that service for you.

To learn more about our welding services call us at 610-582-1118

, contact us online

, or go to our Custom Welding Services

page.