ABRASIVE BLAST CLEANING SERVICES

FEATURING A VARIETY OF ABRASIVE CLEANING MEDIA

*We will also remove any current coating, corrosion, and impurities from your metal projects so that YOU can "DIY" paint or powder application! Email us through the contact menu or give us a call!

HOW ABRASIVE CLEANING WORKS

Abrasive cleaning is a process in which an abrasive such as garnet, aluminum oxide, steel shot or glass bead is propelled at a high rate of speed at an object, thereby removing existing surface impurities, worn finishes or rust.

As an integral part of our

Powder Coating Process, we take our abrasive cleaning services seriously. We have the capabilities to clean parts of all sizes.

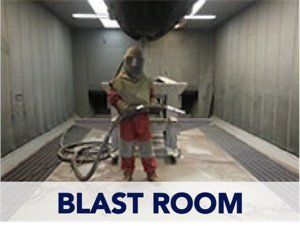

BLAST ROOM

Our full reclaim blast room is our abrasive cleaning work horse. Features and benefits include:

- Up to 10 ton weight capacity

- Room Dimension: 26ft x 12ft

- 10ft ceiling for huge parts

- Full abrasive reclamation means lower prices

ABRASIVE CLEANING MEDIA

ALUMINUM OXIDE

Aluminum Oxide is the most commonly used blast media in blast finishing and surface preparation.

GARNET

Van Industries uses grade 80 garnet in our 4'x4'11"x2'6" blast cabinet. A smaller, yet equally important, part of our Powder Coating operations, most of our smaller parts come through here.

STEEL SHOT

Van Industries' Pangborn steel shot blast cabinet provides an excellent surface finish for powder coating adhesion. We use it for items that are too small for our large blast room, yet too large for our small garnet blasting cabinet. This automated cabinet greatly increases our productivity with its 6'x6'6"x7' capacity.

GLASS BEADING

Used for softer metals and delicate parts, glass beads are a more gentle abrasive. Our glass bead cabinet measures 6'x3'x32".

SODA BLAST

Sodium Bicarbonate (baking soda) blasting is the gentlest of our blasting processes.

Soda blasting is used on items where abrasion of the surface must be avoided. Baking Soda is an extremely friable substance, meaning that as it makes contact with a solid surface it fragments into smaller particles. It is this action that literally "explodes away" surface materials while leaving the underlying item unharmed.

Soda blasting is used for the following applications:

- paint stripping

- automotive restoration

- rust removal

- boat hull cleaning

- residue removal through saponification

Related Blog Posts

What is Abrasive Blasting?