What is CNC Milling?

It's a "subtractive" form of machining. Here's how it works.

Milling

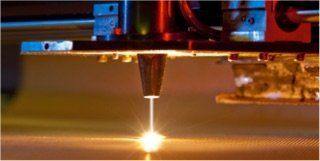

Milling is a form of machining that is used to shape a piece of metal or other solid material by using a rotary cutting tool

(often with multiple cutting edges). The cutting tool removes material as the piece is fed into it. Milling is a “subtractive manufacturing process”

; the raw material is clamped to the table, which moves into the milling cutter removing small bits of metal commonly referred to as chips. The cutter can spin at a variety of speeds (RPMs). The feed rate (usually in inches per minute) is the pace at which the piece moves through the cutter.

Milling, like drilling, uses a rotating cylindrical cutting tool to spin and cut down or shape the material. The difference is that the cutter on a milling machine can move along multiple axes and create a variety of shapes, holes, and slots. The material being cut can also be moved in different directions. Milling Machines are usually grouped by the number of axes

on which they can operate. X and Y designate horizontal movements on a flat plane such as side-to-side and back-to-front. Z represents up-and-down movements. W represents diagonal movements. Most modern milling machines offer 3 to 5 axes.

CNC - Computer Numerical Control

Early milling machines – which have been around since the early 1800’s - were manual. Technological advances created Computer Numeric Control (CNC) milling machines. A CNC mill is controlled and driven by a computer that reads and stores computer codes that are written by a machinist or programmer. This code (a variant of G-code) provides detailed and often intricate step-by-step instructions for how to machine the material. The computer uploads these instructions into the machine tool. CNC revolutionized the milling process by making it more precise and quicker with the ability to produce shapes that would have been impossible using a manual mill.

CNC Milling Applications

Just about any material that can be drilled or cut can be machined using a CNC mill. That includes alloys, aluminum, brass, copper, stainless steel, titanium, PVC, nylon, and other plastics. Depending on the amount of material to be removed and its hardness, the right cutters and drills are selected to complete the job quickly and accurately.

Contact Van Industries for All Your CNC Milling and Machining Needs

A wide range of industries and manufacturing needs can be accommodated by CNC Milling machines including electronics, automotive, medical, and military.

From CNC mills and lathes to 300-ton presses and more, Van Industries is equipped with the best machinery and the technical expertise to produce your parts accurately and efficiently every time!

Click here to learn more about CNC Milling and our Machine Shop services.