LASER VS. WATERJET CUTTING

EACH HAS ITS ADVANTAGES

Our custom manufacturing services include both laser cutting services and waterjet cutting services with reverse engineering capability, complete CAD/CAM capability, same day quotations and competitive pricing. With some of the largest equipment along the east coast, Van Industries has the capacity required for your waterjet or laser cutting needs.

The difference between waterjet cutting and laser cutting lies primarily in thickness cutting ability, material choice and accuracy required for different applications. If your project involves cutting thick material over 1", then you should use waterjet cutting. If your project involves cutting aluminum, copper, brass, titanium, wood, acrylic, plastic or requires no heat affected zones, then you would typically use waterjet cutting, although our new, high-speed Amada laser cutter can also cut some of these materials. If your project involves processing thinner stainless steels, or carbon steels, then you most likely will choose laser cutting. Laser cutting is also a little less expensive, as it uses less consumables than waterjet cutting.

See below for an explanation of some of the key features and distinctions of waterjet and laser cutting.

WATERJET CUTTING

WATERJET OVERVIEW:

Our ultra-high pressure waterjet cutting services include water compressed up to 60,000 psi as a precise and powerful cutting tool that causes no heat affected zones (HAZ) or material distortion. The jet streams generated are capable of cutting material ranging from .0005" thick to 12" thick. Waterjet cutting is most commonly used for cutting aluminum, thick carbon steel and stainless steel, copper, brass, titanium, plastic and rubber.

Abrasive waterjet cutting can pierce or drill holes as small as .030" in diameter (0.004" for water jet without abrasive). All of our waterjet machines are equipped with multiple cutting heads that dramatically enhance the effectiveness of cutting, making our process competitive over other comparable methods. Van Industries also practices lean manufacturing.

SAMPLE WATERJET CUTTING APPLICATION:

Van Industries' process could utilize three heads to cut production time by two-thirds. If the customer had used more conventional methods, the number of holes could cause constant drill breaking and would see an increase in production time. Using waterjet cutting allows for tight nesting of parts which saves on material costs.

Other benefits from this waterjet cutting application include cutting tolerances as close as +/- .003," burr-free parts, low contact force of the cutting stream, no heat affected zones, cutting of nearly all materials, no distortion or warping of materials, and a small kerf width to allow tight nesting and optimal material usage.

Since waterjet cutting utilizes a high velocity, coherent stream of water and abrasive, it can be used to cut most materials. This includes: stainless steel, carbon steel, all tool steels, titanium, aluminum, brass, armor plate, wood, Kevlar, plastics, rubber, UHMW, phenolic, all foams, ceramics, marble, granite, glass, ceramic tile, copper and even Hastelloy.

TYPICAL WATERJET CUTTING APPLICATIONS INCLUDE:

- Shape cutting of 1/4" and thicker aluminum

- Net size cutting of 3/4" and thicker stainless steel

- Blank cutting of parts for final machining

- Short run lots of sheet metal parts

- Screen cutting without burrs or warping

- Converting plate stock to bar

- Precision cuts in 1/2" and thicker mild steel

- All types of hardened materials

- Intricate shapes in delicate materials

- Custom shims in stainless steel and exotic materials

- Tube cutting without affecting its inner diameter and more.

LASER CUTTING

LASER CUTTING OVERVIEW:

On the other hand, our laser cutting services are an efficient option for small to large quantities and irregularly shaped parts. Laser cutting eliminates costly tooling charges and provides a quick turnaround. This method of processing is mostly used for stainless steels or steels up to 5/8" thick.

We currently have two large laser cutting machines on our production floor:

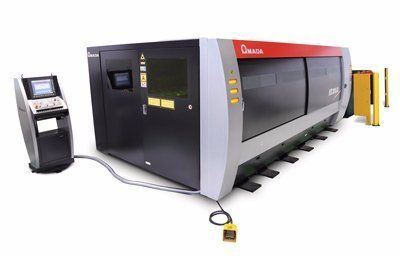

AMADA FLCAJ 4020

Our latest high-tech addition, the Amada FLCAJ laser cutter allows unique materials such as copper and other previously difficult to cut materials to be cut quickly and precisely. Benefits include faster cutting of thin material, superior edge quality, and the ability to laser cut copper, brass, titanium and other materials that were previously difficult to process. Benefits include:

- Cutting area up to 157 x 79"

- Material thickness up to 0.875"

- Blazing cutting speeds up to 4,724" / minute

- Cuts mild steel, stainless steel, aluminum, copper and brass

BYSTONIC BYSTAR 4020

The Bystronic Bystar 4020, has a production rate reaching speeds of 669 inches per minute. This laser-cutting machine provides faster turnaround from job order to shipping. To further ensure that turnaround rate, this machine features lights-out capability as well. Our Mitsubishi LZP 5036-D has a 3300 watt laser and 120"x60" cutting envelope. This laser cutting cell is designed for laser cutting short to long run production. Along with this, we have the capability to process materials such as Hastelloy, stainless steel (SST), aluminum, and carbon steel. Customers often choose laser cutting for its cost effectiveness, burr-free parts, cutting tolerances as close as +/-.003," repeatability +/-.001," and for its cutting capacity up to 3/4" carbon steel and 5/8" stainless steel. With the automatic dual pallet loading system and lights out capability, we can ensure quick turnaround on your custom application cutting.

CONTACT US TO LEARN MORE ABOUT YOUR CUTTING OPTIONS!

Contact us today to request more information on our industrial laser and waterjet cutting services, or to receive a custom quote!